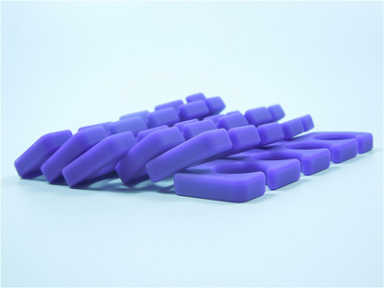

The silicone desiccant presumably we should have heard, it is precisely because the silicone as the main component of the silicone material and water glass solution by adding silanol hydroxyl (as the main adsorption) has a strong adsorption strength, Among the desiccant which can be adsorbed accounted for 70% of the ratio, in the silicone rubber material for solid, white or milky fine solid glue which has the same strong adsorption strength of the surrounding light dust has a strong adsorption strength.

Absorption is the main reason for silicone products stick to dust, but to reduce the adsorption force and sticky dust belong to different processes, silicone materials are anode materials, some of its material can be used as inorganic silicon and silicon in various chemical auxiliary materials In order to reduce the adsorption capacity of silica gel can reduce the silica chain structure of silicon units can be mixed in the raw material while adding a large amount of water to destroy the adsorption strength of silanols and reduce the active ratio of silicone adsorption.

The sticky dust is the main solution to the silicone products company to do, some products after the completion of the appearance of the products submitted to the strict anti-static oil coating can reduce the adsorption strength, and the role of silicone rubber material adsorption efforts on different processes Different benefits, of course, different products have different effects, for consumers to buy daily necessities, gifts and the like is best to have anti-static oil, and industrial parts and electronic accessories is not necessary.